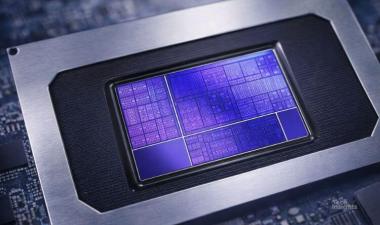

A Look Ahead to the Sustainability of 2nm Processes

Semiconductor fabrication emissions rise with increasing complexity, but carbon neutrality is achievable through refined processes and renewable energy investment.

With the rising complexity of semiconductor fabrication, the associated emissions are growing alarmingly. TechInsights Manufacturing Carbon Module data shows a next-generation 2nm fab based in Oregon will produce ~0.3 million MtCO2e per year and consume over 400 GWh of electricity. Given the reliance on electricity and Scope 2 emissions, fab location also plays a large role, with an equivalent fab based in Taiwan producing almost three times the number of emissions per annum. There are wins to be had. A refined process with high transistor density can greatly reduce emissions on a per-transistor basis. Carbon neutrality in semiconductor manufacturing is possible, but as we will show, it would require a concerted effort and significant investment in renewable energy infrastructure.